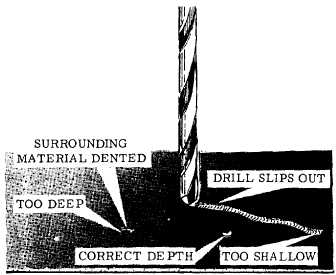

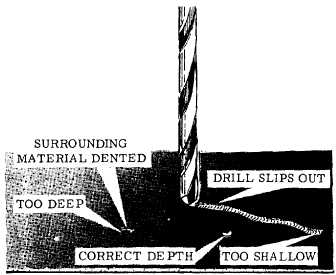

Effigy 13-58.—Lap patch for repairing a crack in stressed skin. To repair cracks, you should e'er drill a pocket-size pigsty (normally chosen stop drilling) in each end of the crack before applying the patch. This is normal] y done by using a No. 30 or No. 40 drill bit. This prevents the concentration of stresses at the noon of the fissure and distributes the stresses around the circumference of the hole. The patch must exist large enough to install the required number of rivets as determined from the rivet schedule indicated for the estimate fabric in the expanse that is damaged. Come across figure thirteen-58. The recommended patch may exist cut in a round, square, rectangular, or diamond shape. The edges are normally chamfered (beveled) to an bending of 45 degrees for approximately one-one-half its thickness. The rivet pattern is laid out on the patch by using the proper edge altitude and spacing. The installation position of each rivet is marked with a center punch. The impression in the cloth made with the eye punch helps to continue the drill from slipping away from the hole being drilled. Meet figure xiii-59. Drill only a minimum number of rivet holes in the patch; normally four will suffice at an angle of 90 degrees to each other. Position the patch over the surface beingness repaired, and ensure that the correct edge distances are being maintained. Drill four holes in the surface being repaired, using the predrilled holes in the patch every bit a pattern for alignment. As each hole is drilled, using the proper temporary fasteners, secure the patch in place. When the patch is temporarily secured, drill the remaining rivet holes through the patch and the surface being repaired. Remove the patch and deburr all rivets holes with a deburring tool or a large drill bit. Prime the repair materials with the proper corrosion-preventive material before the riveting functioning. Secure the patch in position with temporary fasteners to maintain alignment during riveting. Riveting procedures were covered earlier in this chapter. Holes may be repaired in either stressed or nonstressed skin that is less than three-sixteenths of an inch in diameter past filling with a rivet. Drill the hole and install the proper size rivet to make full the hole. For holes three-sixteenths of an inch and larger, you should consult the applicable structural repair transmission for the necessary repair information. The damaged surface area is removed by cutting and trimming the pigsty to a circular, square, rectangular, or diamond shape. The corners of the hole should exist rounded to a minimum of one-fourth of an inch in radius. The lap patch is fabricated and installed in the same fashion as previously explained for repairing cracks. Flush Patches A flush patch consists of a filler patch that is flush with the skin subsequently it is inserted. It is backed up and riveted to a reinforcement plate that, in turn, is riveted to the inside of the skin. This reinforce- ment plate is normally referred to on some repair diagrams every bit the doubler or the backup plate. On some high-functioning aircraft, just the flush patch is permitted in making skin repairs. Affluent patches should be used where aerodynamic smoothness is required. The type of flush patch used depends on the location of the damaged area. One blazon is articulate of internal structures, and the other is not. Like all types of repairs, you must consult the applicable structural repair transmission for the necessary Effigy 13-59.—Drilling holes for rivets. thirteen-43

What Patch May Be Utilized In Repairing Skin Where Aerodynamic Smoothness Is Not Important,

Source: http://navyaviation.tpub.com/14018/css/Flush-Patches-563.htm

Posted by: baileyimince.blogspot.com

0 Response to "What Patch May Be Utilized In Repairing Skin Where Aerodynamic Smoothness Is Not Important"

Post a Comment